Pet Masterbatches

Home » Pet Masterbatches

Members Arena

Diamond Members

- Black Masterbatch

- White Masterbatch

- Colour Masterbatch

- Rubber Masterbatch

- PVC Masterbatch

- Additive Masterbatch

- Pet Masterbatch

- Mono Concentrated

- Roto Pre Masterbatch

- XLPE Masterbatch

- Universal Masterbatch

- Engineering Masterbatch

- Special Effect Masterbatch

- Bio Degradable

- Masterbatch

Platinum Members

- Black Masterbatch

- White Masterbatch

- Filler Compound

- PP Milky Filler For Non

- Woven Products

- Filler Masterbatch

- Colour Masterbatch

- Additive Masterbatch

- Desiccant Masterbatch

- Optical Brightner

- UV Masterbatch

- PPA Masterbatch

- Anti Slip Masterbatch

- Slip Masterbatch

- Fire Retardant Masterbatch

- Modifier

- Transparent Masterbatch

Silver Members

Riviera Polymers Private Limited was envisaged in 1982. The organization had to become a mark to reckon with in the manufacture of Colour and Additive Concentrates and Special Thermoplastic Compounds. Two decades on, we are living as Brand Riviera and remain the front-runner manufacturer of high-quality Masterbatches and Specialty Thermoplastic Compounds in India.

Share Your Requirements to Get the Best Price

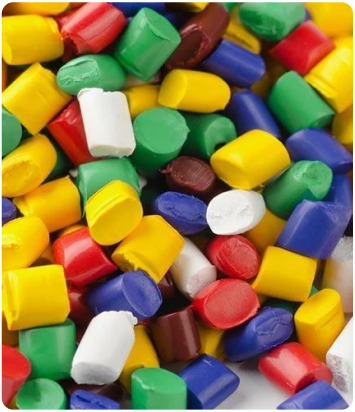

PET Masterbatch for High-Quality and Sustainable Plastics

Improve the quality of your plastic products with our advanced PET Masterbatch! It improves colour, strength, and durability while also providing UV resistance and improved processing. Our premium solutions boost performance and sustainability in the packaging, automotive, and textile industries. Choose Masterbatch Manufacturers for bright and long-lasting effects!

What is PET Masterbatch?

Raw polyethylene terephthalate (PET) materials are mixed with PET Masterbatch, a concentrated blend of colours, additives, and resins, to improve their qualities. This specific composition guarantees enhanced processing capabilities, better mechanical strength, and consistent colouration. This Masterbatch is a crucial part of the plastic production process as it allows producers to produce high-quality plastic products with reliable performance.

Applications of PET Masterbatch Across Industries

- Packaging Industry: Widely used in manufacturing bottles, containers, and films due to its excellent transparency, strength, and recyclability.

- Automotive Sector: Increases the durability of plastic parts found in automobiles, including panels, dashboards, and interior trims.

- Textile Industry: Used in polyester fiber production for making garments, upholstery, and industrial fabrics.

- Electronics and Electricals: Used to provide safety and durability in electronic device casings and insulating materials.

- Consumer Goods: Excellent strength and appearance make it perfect for making toys, cosmetic containers, and kitchenware, among other home items.

How Does PET Masterbatch Enhance Plastic Properties?

- Improved Colour Stability: This guarantees that plastic items have colors that are vivid and durable.

- Enhanced UV Resistance: Protects plastics from degradation due to sun exposure.

- Increased Mechanical Strength: Increases resilience and impact resistance.

- Superior Processability: Improves melt flow characteristics, which simplifies and speeds up processing.

- Sustainability Benefits: Aids in the creation of recyclable, environmentally friendly plastics.

Different Types of PET Masterbatch and Their Uses

- Color Masterbatch: Used to give vibrant and vibrant colors to PET-based products.

- White Masterbatch: High opacity and brightness are available for applications that need a clean, white finish.

- Black Masterbatch: Guarantees excellent UV stability and deep, rich black colouring.

- UV Stabilizer Masterbatch: Increases the product’s resistance to UV rays, extending its useful life.

- Optical Brightener Masterbatch: Improves brightness and clarity for a premium appearance.

- Barrier Masterbatch: Enhances resistance to moisture, gas, and oxygen transmission in packaging applications.

- We also provide Additive Masterbatch, which may be customised to include anti-blocking agents, antioxidants, and processing aids to improve plastic properties for specific performance requirements.

Choosing the Right PET Masterbatch for Your Production Needs

Selecting the best PET Masterbatch depends on several factors, including:

- Application Requirements: Determine whether colour, strength, or barrier qualities are critical.

- Processing Conditions: Choose compositions that work with your manufacturing method, such as injection moulding, extrusion, or blow moulding.

- Environmental Considerations: Choose eco-friendly options that support your sustainability aims.

- Customisation Needs: If standard solutions do not match your needs, we provide unique formulations adapted to your specifications.

Get the Best PET Masterbatch Solutions Today!

Delivering advanced and superior PET Masterbatch solutions that improve your plastic products is our mission at Masterbatch Manufacturers. To help you choose the best masterbatch to maximise your production operations, our knowledgeable staff is available.

Whatever your requirements for greater durability, better coloration, or custom additives, we have the ideal solution for you. Get in touch with us today to see our wide range of PET Masterbatch and Additive Masterbatch products. Let us help you in achieving greater quality, efficiency, and sustainability in your plastic production!

Benefits

Heat Stability

High Clarity

Color consistency

UV resistance

Cost efficiency

Smooth dispersion

Custom shades

Food safe

Strong durability

Easy processing

High gloss

Recyclable

Fast production

Surface finish

Uniform quality

FDA compliant

RoHS certified

Enhanced strength

Printability

Optical brightness

Industrial Applications

PET Water and Beverage Bottles

Cosmetic and Personal Care Containers

Pharmaceutical Packaging

High-Performance Packaging Materials

Food-Grade Containers and Trays

PET Films for Lamination and Printing

Polyester Textile Fibers and Yarns

Automotive Interior Components

PET Sheets for Thermoforming

Transparent Blister Packaging

Retail Product Packaging

Industrial PET Straps

3D Printing PET Filaments

Colored and Opaque PET Preforms

PET Clamshell Containers for Food and Retail Products

Household Item Packaging

Elevating Plastics with Superior Pet Masterbatches

Unmatched quality, performance, and customization for every industry.

Frequently Asked Questions

Our FAQ section provides clear answers to common questions about white masterbatches, from product features to application details. We aim to help you understand how our solutions can improve your plastic products. If you have further inquiries, our team is always ready to assist you.

What is PET Masterbatch?

PET Masterbatch is a concentrated mixture of pigments or additives encapsulated in a PET carrier resin, used to color or modify PET plastic products.

What are the primary uses of PET Masterbatch?

It is mainly used in PET bottles, films, fibers, preforms, and packaging products to add color, UV protection, or other functional properties.

Is PET Masterbatch safe for food-contact applications?

Yes, food-grade PET Masterbatch is formulated to meet FDA and other international safety standards for food and beverage packaging.

Can PET Masterbatch be used in bottle preforms?

Yes, it is widely used in PET preforms to achieve consistent color and transparency in the final blown bottles.

What is the typical addition rate of PET Masterbatch?

Usually, 1% to 5% masterbatch is added to the PET resin, depending on the required color intensity and functionality.

Does PET Masterbatch affect clarity?

No, high-quality PET Masterbatch maintains the natural clarity of PET, especially in transparent applications.

Can I customize colors with PET Masterbatch?

Yes, PET Masterbatch can be customized to match any Pantone or RAL shade for branding or product differentiation.

What types of additives are available in PET Masterbatch?

Common additives include UV stabilizers, anti-block, slip agents, optical brighteners, and anti-oxidants.

Is PET Masterbatch compatible with recycled PET (rPET)?

Yes, it can be used with rPET blends without compromising performance or aesthetics.

How does PET Masterbatch impact processing speed?

It enhances processability and allows for faster and more stable production, especially in high-speed lines.

Is PET Masterbatch suitable for injection molding?

Yes, it performs well in injection molding applications like preforms and caps.

What is the shelf life of PET Masterbatch?

Generally, PET Masterbatch has a shelf life of 12 to 24 months when stored in dry, cool conditions.

Can PET Masterbatch withstand high temperatures?

Yes, it is engineered to withstand high processing temperatures typical of PET extrusion and molding.

What are the advantages of using PET-based carrier resin in masterbatch?

Using PET as the carrier ensures excellent compatibility, dispersion, and no contamination in the end product.

Can PET Masterbatch improve UV resistance?

Yes, UV-resistant PET Masterbatch protects the product from sun damage and color fading.

Is PET Masterbatch suitable for textile applications?

Yes, it is used in coloring PET-based polyester yarns and fibers in the textile industry.

How does PET Masterbatch improve product consistency?

It provides uniform color distribution and performance across all batches, reducing rework and wastage.

Can PET Masterbatch be used for opaque packaging?

Yes, specific formulations are available for full opacity in PET applications such as dairy bottles.

Are PET Masterbatches environmentally friendly?

Many formulations are eco-friendly and compatible with recycling processes.

What testing standards does PET Masterbatch meet?

It typically complies with international standards like FDA, RoHS, REACH, and ISO for safety and performance.

Other Products

Other

Transparent Masterbatches

UV Masterbatch

Special Effect Masterbatches

Engineering Masterbatches

Universal Masterbatches

Biodegradable Masterbatches

Additive Masterbatches

Roto Pre Masterbatch

Mono Concrentrates

XLPE Masterbatches

Rubber Masterbatches

Pet Masterbatches

PVC Masterbatches

Black Masterbatches

Colour Masterbatches