Oxo Bio Degradable Masterbatch

Home » Oxo Bio Degradable Masterbatch

Members Arena

Diamond Members

- Black Masterbatch

- White Masterbatch

- Colour Masterbatch

- Rubber Masterbatch

- PVC Masterbatch

- Additive Masterbatch

- Pet Masterbatch

- Mono Concentrated

- Roto Pre Masterbatch

- XLPE Masterbatch

- Universal Masterbatch

- Engineering Masterbatch

- Special Effect Masterbatch

- Bio Degradable

- Masterbatch

Platinum Members

- Black Masterbatch

- White Masterbatch

- Filler Compound

- PP Milky Filler For Non

- Woven Products

- Filler Masterbatch

- Colour Masterbatch

- Additive Masterbatch

- Desiccant Masterbatch

- Optical Brightner

- UV Masterbatch

- PPA Masterbatch

- Anti Slip Masterbatch

- Slip Masterbatch

- Fire Retardant Masterbatch

- Modifier

- Transparent Masterbatch

Silver Members

Riviera Polymers Private Limited was envisaged in 1982. The organization had to become a mark to reckon with in the manufacture of Colour and Additive Concentrates and Special Thermoplastic Compounds. Two decades on, we are living as Brand Riviera and remain the front-runner manufacturer of high-quality Masterbatches and Specialty Thermoplastic Compounds in India.

Share Your Requirements to Get the Best Price

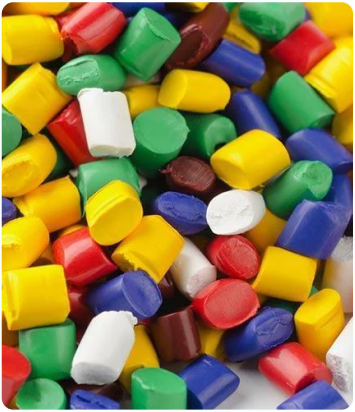

Oxo-Biodegradable Masterbatch: Smart Plastics with Controlled Lifespan

As the world shifts toward eco-conscious solutions, the demand for plastics that degrade safely in the environment has increased dramatically. Oxo-Biodegradable Masterbatch offers an intelligent and cost-effective way to make conventional plastic products degrade after use—without compromising on performance during their intended life.

It allows manufacturers to produce greener plastics while maintaining full control over their usability, strength, and processability.

What is Oxo-Biodegradable Masterbatch?

Oxo-Biodegradable Masterbatch is a specially engineered additive that, when blended with standard polyolefins like PE or PP, initiates oxidative degradation in the presence of oxygen, heat, UV light, and microbial activity.

This masterbatch triggers a two-stage degradation process:

- Oxidation Phase: Plastic polymer chains break down into smaller fragments through exposure to heat, light, and oxygen.

- Biodegradation Phase: These fragments are then consumed by microbes in the environment, converting them into CO₂, water, and biomass.

It is a proven alternative to traditional non-degradable plastics, especially for single-use and short-life products.

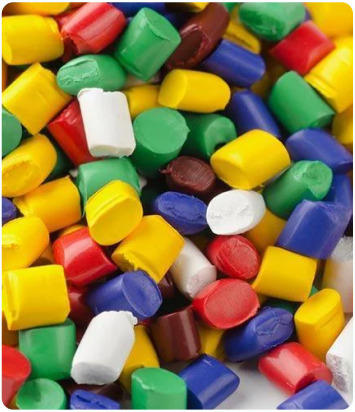

Technical Overview

Parameter | Typical Specification |

Base Carrier | LDPE, LLDPE, universal |

Active Agents | Transition metal salts (Mn, Fe, Co) |

Dosage Level | 1% – 3% (depending on application) |

Processing Temperature | Up to 220°C |

Degradation Onset | After 6–12 months (adjustable) |

Total Degradation Time | 12 to 36 months (based on exposure) |

Standards Support | ASTM D6954, BS 8472 |

How It Works

Oxo-biodegradable masterbatch initiates degradation in two controlled stages:

- Oxidation Stage:

Heat, UV light, and oxygen activate the additive, causing long polymer chains to break into smaller fragments (oxidation). - Biodegradation Stage:

Microorganisms in the soil or composting environment digest these fragments, turning them into CO₂, water, and humus—just like organic matter.

This dual-action makes oxo-biodegradable plastics ideal for open environments where recycling is impractical.

Conclusion

Oxo-Biodegradable Masterbatch offers a practical and scalable solution to reduce plastic pollution. It enables manufacturers to produce products that are functional during use, but degradable after disposal—making it ideal for brands looking to balance performance with sustainability.

Whether you’re in packaging, retail, or agriculture, integrating oxo-biodegradable solutions into your plastic products reflects your commitment to the environment without compromising on quality or cost-efficiency

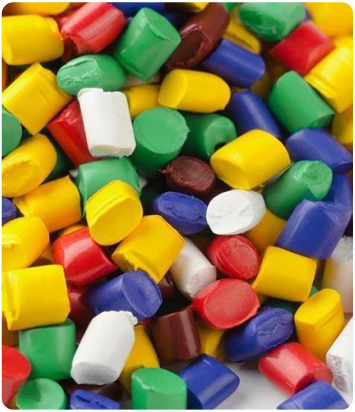

Benefits

Accelerated Degradation

Retains Product Strength Initially

Eco-Friendly End-of-Life

Cost-Effective

Wide Polymer Compatibility

Customizable Degradation Timeline

No Impact on Processing

Supports Regulatory Compliance

Industrial Applications

Shopping & Carry Bags

Disposable Packaging

Agricultural Mulch Films

Hygiene & Medical Disposables

Courier & E-commerce Packaging

Food Packaging Films

Household Goods

Elevating Plastics with Superior Oxo Bio Degradable Masterbatch

Unmatched quality, performance, and customization for every industry.

Frequently Asked Questions

Our FAQ section provides clear answers to common questions about white masterbatches, from product features to application details. We aim to help you understand how our solutions can improve your plastic products. If you have further inquiries, our team is always ready to assist you.

Is oxo-biodegradable the same as compostable?

No. Oxo-biodegradable plastics degrade in open environments, while compostables require industrial composting conditions.

How long does it take for degradation to begin?

Typically after 6–12 months, depending on storage and environmental exposure.

Does it affect product appearance or strength?

No—it maintains all functional properties during intended use.

Can it be used with color or filler masterbatches?

Yes—it is compatible with most additives and pigments.

Does it degrade in landfills?

Yes, if oxygen and microbial activity are present, although degradation is slower.

Is it safe for food-contact products?

Food-grade variants are available—ensure your supplier provides proper certification.

Can it be recycled?

Ideally no—oxo-biodegradable plastics are designed for disposal, not for reprocessing.

Does UV exposure accelerate degradation?

Yes—sunlight and heat are key triggers for the degradation process.

What is the shelf life of a product with oxo-biodegradable masterbatch?

Usually 12 to 24 months, depending on storage conditions.

Is it harmful to soil or plants?

No—it breaks down into non-toxic byproducts safe for the environment.

How is it different from conventional plastics?

It includes a pro-degradant additive that causes breakdown in natural conditions.

Is it approved globally?

Yes—many global brands use oxo-biodegradable packaging in compliance with regional standards.

Can I use it in blown film extrusion?

Absolutely—it’s commonly used for film applications like bags and liners.

Does it leave microplastics behind?

No—the second stage ensures complete biodegradation into biomass.

What industries benefit most from it?

Retail, food packaging, agriculture, medical disposables, and e-commerce.

Can I control how quickly it degrades?

Yes—the additive formulation can be tailored for faster or slower degradation.

Does it require changes in tooling or equipment?

No—standard processing machinery can be used.

Is it more expensive than normal masterbatch?

Slightly higher in cost, but offset by EPR benefits and brand value.

Will it smell or change texture?

No—it’s odorless and stable under normal use.

Where can I buy it in India?

From certified suppliers or through MasterbatchManufacturers.com.

Other Products

Other

Transparent Masterbatches

UV Masterbatch

Special Effect Masterbatches

Engineering Masterbatches

Universal Masterbatches

Biodegradable Masterbatches

Additive Masterbatches

Roto Pre Masterbatch

Mono Concrentrates

XLPE Masterbatches

Rubber Masterbatches

Pet Masterbatches

PVC Masterbatches

Black Masterbatches

Colour Masterbatches

Latest Blogs

That’s why we created a one-stop platform that connects buyers and suppliers in the niche category of Masterbatch worldwide.

Quick Links

Contact Info

Address :

421/C, 4th Floor, Super Mall-1, Gh-0, above SBI Bank, Infocity, Gandhinagar, Gujarat 382007

Phone:

That’s why we created a one-stop platform that connects buyers and suppliers in the niche category of Masterbatch worldwide.

Quick Links

Contact Info

Address

421/C, 4th Floor, Super Mall-1, Gh-0, above SBI Bank, Infocity, Gandhinagar, Gujarat 382007