Engineering Masterbatches

Home » Engineering Masterbatches

Members Arena

Diamond Members

- Black Masterbatch

- White Masterbatch

- Colour Masterbatch

- Rubber Masterbatch

- PVC Masterbatch

- Additive Masterbatch

- Pet Masterbatch

- Mono Concentrated

- Roto Pre Masterbatch

- XLPE Masterbatch

- Universal Masterbatch

- Engineering Masterbatch

- Special Effect Masterbatch

- Bio Degradable

- Masterbatch

Platinum Members

- Black Masterbatch

- White Masterbatch

- Filler Compound

- PP Milky Filler For Non

- Woven Products

- Filler Masterbatch

- Colour Masterbatch

- Additive Masterbatch

- Desiccant Masterbatch

- Optical Brightner

- UV Masterbatch

- PPA Masterbatch

- Anti Slip Masterbatch

- Slip Masterbatch

- Fire Retardant Masterbatch

- Modifier

- Transparent Masterbatch

Silver Members

Riviera Polymers Private Limited was envisaged in 1982. The organization had to become a mark to reckon with in the manufacture of Colour and Additive Concentrates and Special Thermoplastic Compounds. Two decades on, we are living as Brand Riviera and remain the front-runner manufacturer of high-quality Masterbatches and Specialty Thermoplastic Compounds in India.

Share Your Requirements to Get the Best Price

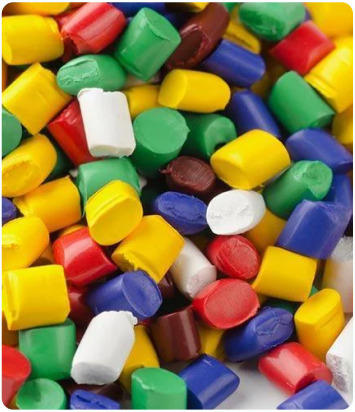

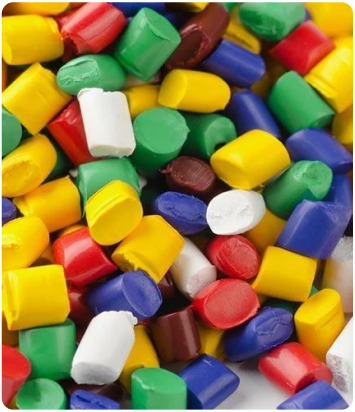

Your Trusted Premium Engineering Masterbatch Manufacturers

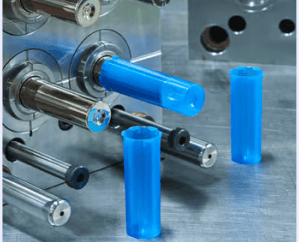

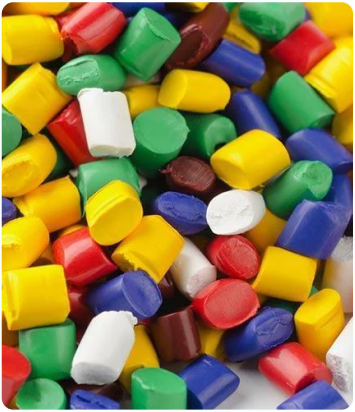

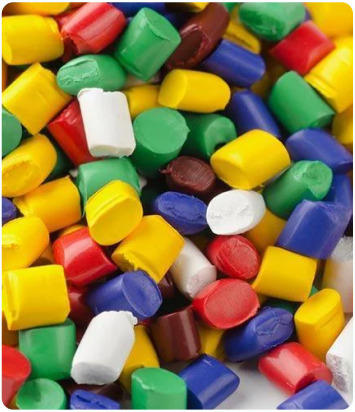

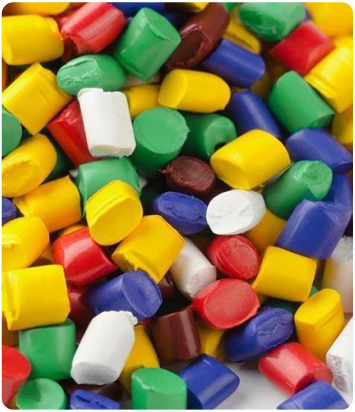

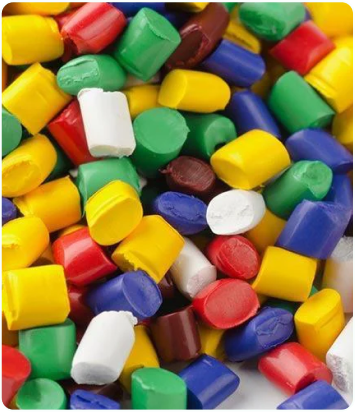

The Engineering masterbatch is essential for improving the functionality and appearance of plastic products. Delivering high-performance colourants, additives, and functional concentrates specifically designed for engineered plastics is our area of expertise as top masterbatch manufacturers. Our solutions are the go-to option for industries all over the world because they guarantee excellent dispersion, durability, and consistency.

Key Benefits of Our Engineering Masterbatch

Precision-Engineered Masterbatch for Superior Performance

Using advanced formulations and premium raw materials, our masterbatch produces unrivalled quality. Our Roto Pre Masterbatch is perfect for flame retardants, UV stabilizers, and custom colours. It performance with high demand in many industries.

Customised Solutions for Diverse Industrial Needs

For the automotive, electronics, machinery, and packaging industries, masterbatch manufacturers offer custom masterbatch solutions. Our Pet Masterbatch additives improve durability, strength, and heat resistance, guaranteeing peak performance for specialty plastic parts.

Advanced R&D or Advanced Productions

Our R&D team pioneers high-performance engineering masterbatch solutions. Automated production meets the changing demands of precision plastic manufacturing across industries by guaranteeing perfect unity, fast turnaround, and reliable delivery.

Eco-Friendly and Sustainable Options

One of the main goals of Masterbatch Manufacturing is sustainability. We provide environmentally friendly masterbatch solutions, such as low-migration colourants and biodegradable additives, to help manufacturers comply with environmental standards without sacrificing functionality.

Masterbatch Solutions for Advanced Features

Our engineering masterbatch finds extensive application in:

High Performance of Polymers

Durability and accuracy are guaranteed by our masterbatch’s proficiency with high-performance polymers of PA, PC, PBT, and ABS. Additionally, we provide Transparent Masterbatch for applications requiring crystal clarity and specialised Masterbatch for packaging.

Increase Plastics for Demanding Environments

This masterbatch increases strength and heat resistance, making it perfect for reinforced plastics that are filled with glass or minerals. At the Masterbatch Manufacturers guarantee exceptional performance in industrial and food-grade applications.

Customized Solution for Technical Components

Our masterbatch provides high-strength, heat-resistant solutions for electronics and automotive applications. With the addition of White Masterbatch for consistency for clarity, we can precisely and dependably meet a wide range of industry demands.

Innovative Masterbatch for Specialized Plastic Solutions

Our masterbatch produces dependable outcomes for a range of applications, including consumer goods and automobiles. It guarantees high performance in even the most demanding plastic manufacturing processes because it is engineered for superior stability.

Your Partner for High-Performance Masterbatch

We provide engineering masterbatch solutions that surpass expectations by fusing advanced technology with industry knowledge. As your partner in manufacturing, we guarantee:

- Reliable quality through thorough testing

- Customised formulations for specific uses

- Technical assistance from conception to manufacturing

- Worldwide dependability with prompt delivery

Contact Us Today

For better solutions, collaborate with top engineering masterbatch producers. With the knowledgeable technical advice and competitive pricing catered to your requirements, get in touch with us right now. Improve the performance and quality of your products by working together to innovate.

Benefits

Improves Heat Resistance

Enhances Mechanical Strength

Provides Superior Impact Resistance

Enables Better UV and Weather Resistance

Enhances Surface Finish and Appearance

Allows Precise Color Matching

Offers Excellent Dimensional Stability

Improves Chemical and Solvent Resistance

Reduces warpage and shrinkage

Ensures uniform dispersion of additives

Supports high-temperature processing

Compatible with Engineering Plastics Like ABS, PC, PA, PBT

Increases Processing Efficiency

Customizable for Flame Retardancy, Antistatic, or Optical Effects

Extends Product Lifespan and Performance

Industrial Applications

Medical Device Housings and Components

Automotive Parts (Dashboards, Trims, Under-the-Hood Components)

Consumer Appliance Components (Washing Machines, Refrigerators, etc.)

High-Performance Packaging Materials

Electrical and Electronic Housings

Construction Materials (Pipes, Panels, Connectors)

Aerospace Interior Parts

Telecom and Networking Device Enclosures

Industrial Equipment Casings

Furniture Components

Battery and Electrical Insulation Parts

Optical and Lighting Components

Wear-Resistant Mechanical Parts

Safety Helmets and Protective Gear

Tool Handles and Engineering-Grade Accessories

Elevating Plastics with Engineering Masterbatchesbatches

Unmatched quality, performance, and customization for every industry.

Frequently Asked Questions

Our FAQ section provides clear answers to common questions about white masterbatches, from product features to application details. We aim to help you understand how our solutions can improve your plastic products. If you have further inquiries, our team is always ready to assist you.

What is Engineering Masterbatch?

Engineering Masterbatch is a concentrated blend of additives or pigments specifically formulated for engineering plastics like ABS, PC, PA, and PBT to enhance their performance or appearance.

Which polymers are Engineering Masterbatches compatible with?

They are compatible with engineering-grade plastics such as ABS, PC, PA (Nylon), PBT, PET, PPS, and more.

What industries use Engineering Masterbatch?

Used in automotive, electrical, electronics, appliances, medical, and industrial components.

Can it be customized for specific properties?

Yes, engineering masterbatches can be tailored for flame retardancy, UV resistance, antistatic behavior, optical clarity, and more.

How does it improve thermal stability?

By incorporating heat stabilizers and high-temperature-resistant carriers, it helps engineering plastics perform better under thermal stress.

Is Engineering Masterbatch suitable for high-speed processing?

Yes, it enhances processability and maintains consistency even in high-speed molding or extrusion.

Does it affect the mechanical strength of the base polymer?

When formulated correctly, it enhances strength, impact resistance, and dimensional stability.

What are typical applications in the automotive industry?

Used for dashboards, trims, under-hood components, and high-heat areas where durability is essential.

Can it be used for electrical insulation applications?

Yes, it improves insulation properties and flame resistance for components like switchgear and cable housings.

Is color matching possible with Engineering Masterbatch?

Absolutely. It offers precise and consistent color matching for aesthetic and branding purposes.

Does it support regulatory compliance (e.g., RoHS, REACH)?

Yes, formulations can be made to meet industry-specific regulations like RoHS, REACH, or UL standards.

Is Engineering Masterbatch compatible with medical-grade plastics?

Yes, special grades are available that meet biocompatibility and sterilization requirements.

Can it enhance chemical resistance in plastics?

Yes, specific additives in the masterbatch can increase resistance to oils, solvents, and acids.

How does it impact recyclability?

It can be designed to support closed-loop systems or controlled degradation based on application needs.

Does it affect molding cycle time?

Yes, it often reduces cycle time by improving flow and thermal behavior.

Are Engineering Masterbatches available in pellet form?

Yes, they are commonly supplied in pellet form for ease of dosing and mixing.

What is the shelf life of Engineering Masterbatch?

Typically 12 to 24 months when stored in cool, dry conditions away from sunlight and moisture.

Can it be used in transparent engineering plastics?

Yes, special optical-grade masterbatches can be used in clear resins like PC or PET.

What is the recommended dosage?

Generally ranges from 1% to 5%, depending on the desired performance and base polymer.

How does it improve surface finish?

By enhancing flow and filler dispersion, it results in smoother, glossier, and defect-free surfaces.

Other Products

Other

Transparent Masterbatches

UV Masterbatch

Special Effect Masterbatches

Engineering Masterbatches

Universal Masterbatches

Biodegradable Masterbatches

Additive Masterbatches

Roto Pre Masterbatch

Mono Concrentrates

XLPE Masterbatches

Rubber Masterbatches

Pet Masterbatches

PVC Masterbatches

Black Masterbatches

Colour Masterbatches

That’s why we created a one-stop platform that connects buyers and suppliers in the niche category of Masterbatch worldwide.

Quick Links

Contact Info

Address :

421/C, 4th Floor, Super Mall-1, Gh-0, above SBI Bank, Infocity, Gandhinagar, Gujarat 382007

Phone:

That’s why we created a one-stop platform that connects buyers and suppliers in the niche category of Masterbatch worldwide.

Quick Links

Contact Info

Address

421/C, 4th Floor, Super Mall-1, Gh-0, above SBI Bank, Infocity, Gandhinagar, Gujarat 382007