Black Masterbatches Manufacturers

Home » Black Masterbatches

Black Masterbatches Manufacturers - Members Arena

Diamond Members

- Black Masterbatch

- White Masterbatch

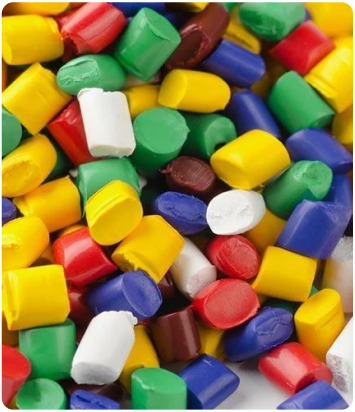

- Colour Masterbatch

- Rubber Masterbatch

- PVC Masterbatch

- Additive Masterbatch

- Pet Masterbatch

- Mono Concentrated

- Roto Pre Masterbatch

- XLPE Masterbatch

- Universal Masterbatch

- Engineering Masterbatch

- Special Effect Masterbatch

- Bio Degradable

- Masterbatch

Platinum Members

- Black Masterbatch

- White Masterbatch

- Filler Compound

- PP Milky Filler For Non

- Woven Products

- Filler Masterbatch

- Colour Masterbatch

- Additive Masterbatch

- Desiccant Masterbatch

- Optical Brightner

- UV Masterbatch

- PPA Masterbatch

- Anti Slip Masterbatch

- Slip Masterbatch

- Fire Retardant Masterbatch

- Modifier

- Transparent Masterbatch

Silver Members

Riviera Polymers Private Limited was envisaged in 1982. The organization had to become a mark to reckon with in the manufacture of Colour and Additive Concentrates and Special Thermoplastic Compounds. Two decades on, we are living as Brand Riviera and remain the front-runner manufacturer of high-quality Masterbatches and Specialty Thermoplastic Compounds in India.

Share Your Requirements to Get the Best Price

Leading Black Masterbatch Manufacturers Globally

The Multifaceted Manufacturing Infrastructure

The complex nature of the masterbatch industry demands a refined solution. Frequently, the buyers and suppliers lack the expertise required to build up the perfect partner providing endurance of quality, innovation support, and service with full reliability. This complication has encouraged the need for some highly specialized platforms making it possible for additive manufacturing disciplines to connect and interact in an open, operative environment.

Black Masterbatch Market Structure Overview

While black masterbatch mainly acts as a colorant itself, it is also a composite of the following:

• Clouding Agents

• Probably the most efficient in dispersing black pigments

• Polymeric carriers for convenient use with different polymers

• Performance-boosting additives that make the polymer resistant to sunlight, heat, and other environmental degradation.

Selecting the perfect black masterbatch would significantly give the obscurity to standard plastic, for it would assume character and thrill whilst such high-performance products had come into being, thus grabbing spots in, say, automotive, construction, and packaging sectors.

Manufacturing the Best: From an Indian Outset

In the black masterbatch business, India is a torchbearer in producing the highest quality black masterbatches and performing innovative activities globally for all other manufacturers to mimic. Such manufacture of black masterbatches at the premium ends means they impart the following features:

Advanced Technological Infrastructure

- Modern production setups for best production.

- Precision-engineering for constant quality output and international quality standards

- Researching and developing activities for continual upgrades.

Stringent Quality Control

- Full systems of quality checks, qualifying for sustainable high-quality colour, dispersal, and prevention of any aesthetic imitations due to material behaviour.

- Complete adherence to quality, ISO, and ASTM standards.

- Customization Capabilities

- They construct tailor-made solutions to fit the unique specifications of their industry.

- Unique stipulation of formulations even for some specific applications.

- Persuasive support services, technically, organised for troubleshooting and subsequent optimizations.

Technical Innovations in the Production of Black Masterbatch

Material Selection

The selection of raw materials carries immense weight in determining the quality of the black masterbatch. The essentials are:

- Added to the exact level of carbon black pigment, those should remain deep black throughout.

- The ability to be used with a wide range of polymer types including polyethylene and polypropylene.

- Performance considerations in the end-use applications.

Advanced Manufacturing Techniques

Highly developed production methods are used by modern black masterbatch manufacturers, such as:

- The Nano-Particle Dispersion Technology helps in the uniform distribution of pigments and additives.

- Precision Compounding contributes positively to consistency and quality of black masterbatch.

- Advanced Extrusion Processes, thus increasing efficiency and scalability.

The Market Dynamics

There are features in the black masterbatch market such as:

- Increasing demand in various sectors, like automobiles, packaging, building, and consumer goods.

- A growing pressure towards sustainable manufacturing, pertaining to environmentally friendly production methods and recyclable materials.

- Innovation in technology fleet, revealing branded smart additives and new formulations.

Principal Application Areas

Black masterbatch finds applications across various industries:

- Automotive Industry: Offering high durability and resistance towards ultraviolet rays in the plastic parts.

- Consumer Electronics: They aim at overall improvements in the aesthetics and function of the product.

- Packaging Solutions: Best engineering with colour consistency and resilience.

- Construction Materials: Adding texture and strength, improving durability of products.

- Agricultural Equipment Manufacturers: Render the raw materials resistant to outdoor elaborations as they excel in performance.

How to Choose the Right Masterbatch Manufacturer?

For buyers who want to optimize black masterbatch solutions, the right thinking is mandatory. The most important factors include:

Technical Expertise

- Thorough knowledge of polymer science.

- A track record of innovation established to date.

- Commitment to training and development.

Quality Certifications

- Conformity to ISO standards.

- Compliance with quality standards appropriate to the industry.

- Recognition by international bodies.

Sustainability initiatives

With more green legislation gathering momentum and buyers leaning towards environmentally viable products, black masterbatch manufacturers could seize opportunities such as:

- Formulating solar composts or bio-based masterbatches.

- Comparison of a worth case business module with other green industries: constructive co-operations can develop green enterprise options.

Emerging Market Demand in Emerging Economies

The prevailing industrial frontrunners of Vietnam, Indonesia as well as Brazil may open new vistas for black masterbatch organizations. Expanding there or partnering in these industrial settings can catapult growth for you.

Innovative Partnerships

Joining hands with the automotive and packaging industries in rolling these high-performance advanced products catering to particular needs of the industry through JVs can be path-breaking.

Conclusion: Why Masterbatch Manufacturers Are the Best Partners

The black masterbatch industry is wrapped in layers. In addition to technological innovation, quality standards are maintained strictly. One with a customer-centric marketing strategy would earn the trust of many. It is really important to identify shades of black before going out for the right partner!

The black Indian masterbatch manufacturers set the precedence of technologies, customizations, and quality securements, leading all the way. By joining such a group beneath Masterbatch Manufacturers, one may benefit from the best network of international suppliers who are esteemed as indispensable and sacred by virtue of absolute customer coverage. This partnership respects buyers and vendors and conducts effective and trustworthy transactions for the completion of every project.

Step into the black masterbatch world, where you will never settle down for anything short of the best and reliability. Choose the platform to your benefit and explore more about their offerings and how they could assist your business in expanding through Masterbatch Manufacturers. Trust Masterbatch Manufacturers, “where innovation meets quality,” to convert black masterbatch into your reality. It is your point of excellence and uniqueness in the world of black masterbatch; it promises to hold up in integrity, innovation, and customer satisfaction.

Benefits

High Opacity

UV Resistance

Color Uniformity

Thermal Stability

Weather Resistance

Cost-Effective

Improved Strength

Scratch Resistance

Anti-Static Properties

Wide Compatibility

Industrial Applications

Packaging

Automotive

Agriculture

Construction

Electrical and Electronics

Textiles, Woven &

Non Woven Fabrics

Water Tanks

Elevating Plastics with Superior Black Masterbatches

Unmatched quality, performance, and customization for every industry.

Frequently Asked Questions

Our FAQ section provides clear answers to common questions about white masterbatches, from product features to application details. We aim to help you understand how our solutions can improve your plastic products. If you have further inquiries, our team is always ready to assist you.

What is black masterbatch?

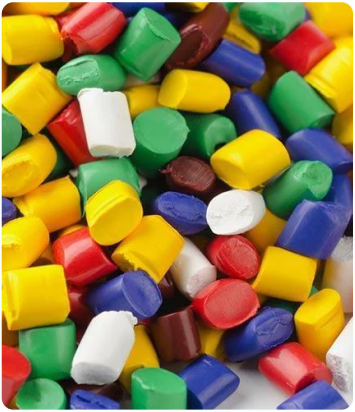

Black masterbatch is a concentrated mixture of carbon black, polymer carrier, and additives used for coloring plastics.

What are the primary applications of black masterbatch?

It is used in automotive, packaging, agriculture, electrical, textiles, and construction industries.

What makes black masterbatch different from black pigment?

Black masterbatch is a pre-dispersed, easy-to-use form, whereas black pigment requires additional processing.

What are the benefits of using black masterbatch?

It provides high opacity, UV resistance, thermal stability, and cost-effectiveness.

Can black masterbatch improve UV protection?

Yes, it enhances UV resistance, extending the lifespan of plastic products.

Is black masterbatch compatible with all polymers?

It is available in different formulations for PE, PP, PET, PVC, ABS, and more.

How is black masterbatch used in the automotive industry?

It is used in bumpers, dashboards, and trims for color uniformity and UV resistance.

Does black masterbatch affect mechanical properties?

Yes, it improves strength, durability, and scratch resistance.

Is black masterbatch cost-effective?

Yes, it reduces the need for high-pigment loadings and improves processing efficiency.

Can black masterbatch be used in food packaging?

Yes, but food-grade formulations must be used for compliance with safety regulations.

What is the recommended dosage of black masterbatch?

Typically 1-5%, depending on the desired color intensity and application.

How does black masterbatch affect processing conditions?

It improves melt flow and dispersion, enhancing production efficiency.

Can black masterbatch be customized?

Yes, manufacturers offer custom formulations based on specific requirements.

Does black masterbatch impact recyclability?

It depends on the carrier resin; some formulations are more recyclable than others.

What is the role of carbon black in black masterbatch?

Carbon black provides deep coloration, UV resistance, and improved mechanical properties.

Is black masterbatch suitable for extrusion and injection molding?

Yes, it is widely used in both processing methods.

How does black masterbatch enhance electrical applications?

It improves insulation, anti-static properties, and durability in cables and conduits.

Can black masterbatch be used in textile fibers?

Yes, it provides deep black coloration and enhances fiber strength.

What is the shelf life of black masterbatch?

Typically 1-2 years if stored properly in a cool, dry place.

Where can I buy high-quality black masterbatch?

From masterbatch manufacturers and suppliers specializing in plastic additives.

Other Products

Other

Transparent Masterbatches

UV Masterbatch

Special Effect Masterbatches

Engineering Masterbatches

Universal Masterbatches

Biodegradable Masterbatches

Additive Masterbatches

Roto Pre Masterbatch

Mono Concrentrates

XLPE Masterbatches

Rubber Masterbatches

Pet Masterbatches

PVC Masterbatches

Black Masterbatches

Colour Masterbatches