Walk into any store, and what catches your eye first? The packaging. Shiny, colourful, smooth, and durable. But behind that perfect look, there’s one unsung hero – Filler Master batch.

Most people don’t even know it exists, yet it silently drives cost savings, strength, and performance in plastic packaging.

Let’s be honest, the packaging world is changing fast – and Filler Master batch has turned out to be a total game changer.

What Exactly Is Filler Master batch?

Before we jump in, let’s make this simple.

Filler Master batch is a concentrated mix of calcium carbonate (CaCO₃) or other mineral fillers blended with a plastic carrier resin. It’s added to plastic during processing to improve strength, reduce cost, and give better texture or finish.

In plain words, it’s like an enhancer – it makes plastic smarter, cheaper, and stronger at the same time. And when it comes to the packaging industry, it’s a true blessing.

Why Packaging Needs Filler Master batch

Packaging is not just about covering a product. It includes security, looks, and price.

Manufacturers are in search of good-looking, long-lasting, and economical packaging films and bags.

This is where Filler Master batch steps in like a silent saviour. It solves multiple problems in one go.

Let’s break down how it changes the game.

1. Major Cost Reduction

To be honest, plastic raw material prices have been on the rise for many years now. Every producer is searching for ways to cut down on production costs while keeping the quality unaltered.

Filler Master batch allows the producers to mix expensive polymer resin in the proper fraction with cheap fillers like calcium carbonate.

For example –

If the polymer resin costs ₹120 per kg, and the Filler Master batch costs ₹60 per kg, mixing even 30% can bring down the overall cost by ₹18–₹20 per kg.

Now imagine that across tons of production – that’s huge savings.

No wonder it’s loved in the packaging world.

2. Improved Film Strength and Thickness

Many people think adding fillers makes plastic weak. But that’s not right.

Filler Master batch, when properly used, gives the end product the advantages of better stiffness, tear strength, and more efficient printing.

Packaging films made using it feel smoother, stronger, and more premium. That’s why you’ll find it in:

- Carry bags

- Food packaging films

- Shopping pouches

- Garbage liners

- Stretch wraps

It helps control film thickness while keeping it durable. Smart move, right?

3. Better Surface Finish

Let’s be honest – nobody likes dull or uneven packaging.

Filler Masterbatch improves surface smoothness and gives that professional matte or glossy finish (depending on the type). It also helps control the transparency of films, which is very important in modern packaging.

That’s why premium packaging brands use it – to make their bags and films feel high-end, not cheap.

4. Heat and Process Stability

When packaging materials go through high-temperature processing, they can get damaged or lose color.

But Filler Master batch stabilizes the melt flow and improves thermal resistance. It makes processing easier and keeps the final product more stable – no breaks, no warping, just clean output.

In simple words, it behaves well under pressure.

To put it in a nutshell, it can take the beatings and still stands tall.

5. Eco-Friendly Approach

Always be nice – to the planet as well as to people.

Filler Masterbatch amounts to a great deal less of virgin polymer, being the only one in production. So there is less plastic consumption, less waste, and less of a carbon footprint.

In the era of sustainable packaging, this is a huge thing. It assists brands in moving towards eco-friendly packaging without sacrificing performance.

6. Enhanced Printability

Ever noticed how clear and bright some prints look on packaging? That’s because the film’s surface has good ink adhesion.

Filler Masterbatch helps improve that. The packaging film gets a better surface texture, which holds ink and design patterns more effectively.

The result? Clean, sharp, professional-looking packaging every single time.

7. Anti-Blocking and Anti-Slip Properties

You might not think of this, but when plastic films stick together or tear during processing, it’s a nightmare for manufacturers.

Filler Master batch helps by adding a slight roughness that prevents blocking, making film rolls easier to unwind.

Basically – less hassle, more productivity.

Why the Packaging Industry Can’t Ignore It

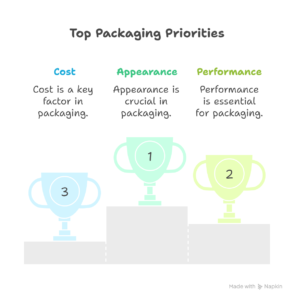

Let’s be honest, in packaging, appearance + performance, + cost are everything.

And Filler Master batch ticks all three boxes effortlessly.

It’s not just about cutting costs; it’s about smarter material engineering.

That’s why companies making shopping bags, food wraps, and even industrial films can’t think of production without it.

Real-World Impact

Across India and abroad, packaging manufacturers are saving lakhs by using the Filler Master batch.

It reduces polymer use, improves processing speed, and enhances quality.

Even small-scale filmmakers can benefit – and that’s why it’s called a game changer.

To be frank, if you’re in the packaging business and not using it, you’re missing out on serious efficiency. Explore advanced Filler Master batch products designed for durable packaging films.

Future of Filler Master batch in Packaging

The future looks bright – and lighter (literally).

Manufacturers are now developing bio-based and recyclable Filler Master batch versions. These not only reduce cost but also support sustainable goals.

In the next few years, we’ll see eco-smart packaging films made entirely using recyclable filler compounds. Black, white, transparent, matte – every variant is getting greener and better.

Stay connected on Facebook and Instagram for new product launches and manufacturing tips.

Conclusion

If packaging was your product’s face, then Filler Master batch was the hidden ingredient making that face more attractive, and it was less expensive too.

No fancy buzzwords, just real benefits.

To be honest, it’s not just a product – it’s a revolution quietly reshaping the packaging industry.

And the best part? It’s doing it without you even noticing.

FAQs About Filler Master batch

- Why is the Filler Masterbatch used in packaging?

Let’s be honest – it cuts cost, boosts strength, and improves film quality. That’s exactly what packaging needs.

- Does the Filler Masterbatch affect product quality?

Not if used properly. In fact, it improves finish, strength, and durability.

- Is it green?

Definitely, the use of today’s Filler Master batch is a step in the recycling process, and it also helps in lessening the quantity of plastic waste. So, it’s good for business and the planet.

- Can it be used in all types of films?

Mostly yes – from carry bags to food packaging, it works well in PE, PP, and other common polymers.

- What is the proper amount to add?

Honestly, the general practice is to add about 20 to 40 percent; however, it will vary with the installed thickness and the specific configuration of your equipment.