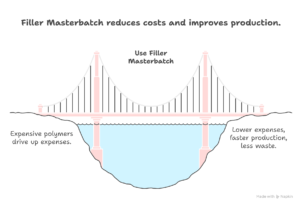

Every manufacturer in the plastic industry, which is highly competitive nowadays, is looking at different ways to cut down on the cost of production without necessarily sacrificing the quality of their products. And that’s exactly where The Filler Masterbatch comes in. It’s not just a material-it’s a smart solution that helps companies save big on raw material costs while maintaining product strength, flexibility, and finish.

Let’s dive deep and see how Filler Masterbatch actually helps cut down raw material expenses in the simplest and most practical way possible.

What Exactly Is Filler Masterbatch?

To be frank, before we understand how it saves money, we need to know what it is.

Filler Masterbatch is a highly concentrated mix of fillers such as Calcium Carbonate (CaCO₃), talc, or any other type of filler mixed with a polymer base and additives. The form it usually takes is pellets and it is added to the production process together with raw polymers such as PP, PE, or HDPE.

The main goal? To replace a part of the expensive polymer resin with a cheaper yet efficient filler-without losing product quality.

Simple idea, big impact!

How Filler Masterbatch Reduces Raw Material Costs

1. Replaces Costly Polymers – Filler Masterbatch

Let’s be honest-polymer resins are costly. When you add Filler Masterbatch, you’re replacing 20%–50% of your polymer with fillers like CaCO₃, which are much cheaper. This immediately reduces your raw material cost per kg without sacrificing mechanical properties.

Example:

If the cost of polymer is ₹120/kg and filler masterbatch costs ₹60/kg, using 30% filler can reduce the blended cost to around ₹96/kg.

Now multiply that saving by 1000 kg-and you see the magic!

2. Improves Production Efficiency

Another hidden benefit is speed. Filler Masterbatch improves heat conductivity, so plastic melts and cools faster.

That means:

- Less electricity consumption

- Shorter cycle time

- More output per hour

Basically, you get higher productivity with lower energy use. To be frank, that’s a win-win for every manufacturer.

3. Reduces Material Waste

When you mix filler masterbatch correctly, it helps maintain dimensional stability and better flow during molding or extrusion. This means fewer rejections, fewer defects, and less raw material wasted.

Let’s be honest, nobody likes seeing material go into the dustbin.

4. Enhances Surface Finish and Strength

You might think adding fillers would reduce quality-but jokes apart, that’s not true when used right. Filler Masterbatch can actually improve stiffness, printability, and opacity. So, instead of buying expensive coated polymers or additives, manufacturers can achieve similar effects using fillers-saving even more cost.

5. Makes Transportation Cheaper

The reason for this is that the filler material, calcium carbonate, is very heav,y which means that the overall volume of material can be decreased for the same production process.

This consequently leads to lower costs for storage and transportation.

Be kind to your budget-it deserves a break too!

Industries Benefiting from Filler Masterbatch

Filler Masterbatch is used in almost every plastic sector. Some instances are given below:

- Packaging Films (LDPE, HDPE bags, stretch film)

- Injection Molding Products (buckets, chairs, containers)

- Blow Molding (bottles, jars)

- Woven Sacks (fertilizer, cement bags)

- Non-woven Fabric (medical, agricultural use)

Filler Masterbatch is used by everyone, from small-scale producers to global brands, to cut costs and enhance performance. Check our complete Filler Masterbatch range for cost-saving options.

Real Example: Cost Saving Breakdown

Let’s take a simple scenario.

A company produces 1000 kg of plastic film every day using pure polymer.

If they switch to 30% Filler Masterbatch, here’s what happens:

Material Type Price (₹/kg) Usage % Cost (₹/kg)

Polymer Resin 120 70% 84

Filler Masterbatch 60 30% 18

Total Cost – 100% ₹102/kg → ₹84/kg = ₹18 Saved/kg

That’s an ₹18,000 saving per ton!

Imagine how much that adds up to monthly or yearly.

Environmental Benefit Too

Reducing the usage of raw polymers means using less petroleum-based materials too.

Thus, besides saving money, you are being more considerate to the earth.

Less plastic = Less carbon footprint.

To be honest, it’s a tiny step toward a sustainable future.

Tips to Use Filler Masterbatch Effectively

- Always check the compatibility with your polymer type (PP, PE, etc.)

- Maintain proper mixing ratio (usually 20%–40%)

- Choose a trusted supplier for consistent quality

- Test batch samples before full production

- Store in a dry, cool area to maintain performance

Follow us on Instagram and Facebook for new product updates and industry insights.

Conclusion

Filler Masterbatch is not just a filler-it’s a profit booster. It cuts down polymer costs, saves energy, enhances performance, and even supports sustainability.

Let’s be honest, in the world of tight margins, every rupee matters. And using Filler Masterbatch smartly can make a big difference in your bottom line.

So next time you plan your production budget, remember-sometimes the smartest way to grow is by filling wisely.

FAQs

- What is Filler Masterbatch made of?

It’s mainly made from calcium carbonate or talc powder, mixed with polymer resin and additives. Simple but super effective.

- Does using Filler Masterbatch affect product quality?

To be frank, not if you use the right ratio. In fact, it often improves stiffness and appearance.

- What is the recommended amount of Filler Masterbatch to add?

Normally, it ranges from 20% to 40%, depending on your product and performance requirements.

- Can Filler Masterbatch be employed with recycled plastic?

Sure, definitely! It blends well and helps reduce the overall cost in recycling processes, too.

- Why do manufacturers prefer it?

To be honest-money saver, a quality keeper, and production easier.