Slip Masterbatch

Home » Slip Masterbatch

Members Arena

Diamond Members

- Black Masterbatch

- White Masterbatch

- Colour Masterbatch

- Rubber Masterbatch

- PVC Masterbatch

- Additive Masterbatch

- Pet Masterbatch

- Mono Concentrated

- Roto Pre Masterbatch

- XLPE Masterbatch

- Universal Masterbatch

- Engineering Masterbatch

- Special Effect Masterbatch

- Bio Degradable

- Masterbatch

Platinum Members

- Black Masterbatch

- White Masterbatch

- Filler Compound

- PP Milky Filler For Non

- Woven Products

- Filler Masterbatch

- Colour Masterbatch

- Additive Masterbatch

- Desiccant Masterbatch

- Optical Brightner

- UV Masterbatch

- PPA Masterbatch

- Anti Slip Masterbatch

- Slip Masterbatch

- Fire Retardant Masterbatch

- Modifier

- Transparent Masterbatch

Silver Members

Riviera Polymers Private Limited was envisaged in 1982. The organization had to become a mark to reckon with in the manufacture of Colour and Additive Concentrates and Special Thermoplastic Compounds. Two decades on, we are living as Brand Riviera and remain the front-runner manufacturer of high-quality Masterbatches and Specialty Thermoplastic Compounds in India.

Share Your Requirements to Get the Best Price

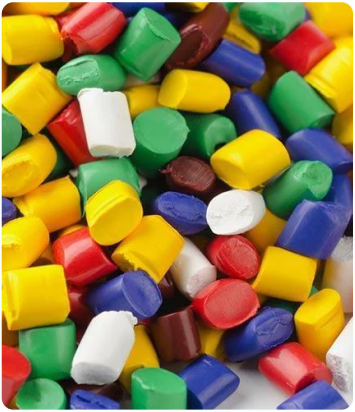

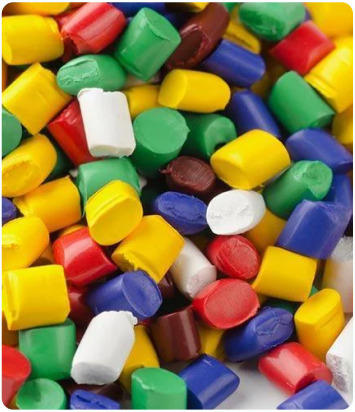

Slip Masterbatch: Enhancing Film Smoothness & Processing Efficiency

In plastic film production, surface friction can lead to processing inefficiencies, sticking, wrinkling, and difficult winding or unwinding. Slip Masterbatch is a vital additive designed to reduce the coefficient of friction (COF) on the film surface, improving processability, handling, and overall product quality.

Whether you manufacture food-grade films, packaging rolls, or industrial wraps, Slip Masterbatch ensures a smoother production experience and superior end-use performance.

What is Slip Masterbatch?

Slip Masterbatch is a concentrated formulation containing slip agents (commonly fatty acid amides like erucamide or oleamide) dispersed in a carrier resin such as PE or PP. These slip agents migrate to the surface of the plastic film and form a thin lubricating layer, significantly reducing surface friction between film layers or machine parts.

It is essential in high-speed film extrusion, packaging lines, and lamination processes.

Technical Specifications

Parameter | Details |

Active Ingredient | Erucamide / Oleamide / Stearamide |

Carrier Resin | LDPE / LLDPE / PP / Universal Resin |

Appearance | White or translucent pellets |

Typical Dosage | 0.5% – 3.0% (varies by COF target) |

COF Reduction Range | ~0.2 to 0.4 |

Migration Time | 6 to 48 hours after film formation |

Processing Compatibility | Blown Film, Cast Film, Extrusion |

Food Contact Grade | Available on request |

Black Masterbatch: Useful to the Global Manufacturing Scenario

While black masterbatch mainly acts as a colorant itself, it is also a composite of the following:

• Clouding Agents

• Probably the most efficient in dispersing black pigments

• Polymeric carriers for convenient use with different polymers

• Performance-boosting additives that make the polymer resistant to sunlight, heat, and other environmental degradation.

Selecting the perfect black masterbatch would significantly give the obscurity to standard plastic, for it would assume character and thrill whilst such high-performance products had come into being, thus grabbing spots in, say, automotive, construction, and packaging sectors.

How Slip Masterbatch Works

Once the film is formed, the slip additive migrates to the surface, creating a lubricated layer that:

- Reduces static and friction,

- Prevents film blocking,

- Enhances separation between film layers.

This migration is controlled and gradual, ensuring long-term effectiveness without affecting film transparency or sealability.

Conclusion

Slip Masterbatch is a critical enhancer for film producers aiming for faster production, minimal sticking, and better product finish. It brings down friction while maintaining product integrity, enabling smooth performance across packaging, industrial, and hygiene applications.

Whether you’re producing everyday wrappers or technical films, this masterbatch keeps your lines running efficiently and your products looking premium.

Benefits

Reduces Surface Friction

Prevents Blocking

Improves Packaging Speed

Cost-Effective

Enhances Handling

Uniform Surface Lubrication

Food-Grade Options Available

Compatible with PE, PP & Multilayer Films

Industrial Applications

Food Wrapping Films

Flexible Packaging Films

Shrink & Stretch Wrap Films

Agricultural Films

Hygiene & Non-Woven Films

Automotive & Industrial Sheets

Elevating Plastics with Superior Slip Masterbatch

Unmatched quality, performance, and customization for every industry.

Frequently Asked Questions

Our FAQ section provides clear answers to common questions about white masterbatches, from product features to application details. We aim to help you understand how our solutions can improve your plastic products. If you have further inquiries, our team is always ready to assist you.

What is the purpose of Slip Masterbatch?

It reduces surface friction (COF) to improve handling and reduce film sticking.

What is COF and why is it important?

COF (Coefficient of Friction) affects how easily films move across surfaces. Lower COF = smoother processing.

How much slip masterbatch should I use?

Typical dosage is 0.5% to 3%, depending on application and COF requirement.

Can it be used with other additives?

Yes—compatible with antiblock, UV, antistatic, and color masterbatches.

Is it safe for food contact films?

Food-grade versions are available upon request.

Does it affect film transparency?

No—formulated to retain optical clarity when used correctly.

How long does it take to activate?

Surface migration takes 6–48 hours after film extrusion.

Is it suitable for multilayer films?

Yes—often used in outer layers to reduce friction during processing.

Will it affect sealing strength?

Only if overdosed. Optimal dosage ensures no impact on heat sealing.

What causes excessive slip or migration?

Overdosing or incorrect additive selection—customized formulations solve this.

Other Products

Other

Transparent Masterbatches

UV Masterbatch

Special Effect Masterbatches

Engineering Masterbatches

Universal Masterbatches

Biodegradable Masterbatches

Additive Masterbatches

Roto Pre Masterbatch

Mono Concrentrates

XLPE Masterbatches

Rubber Masterbatches

Pet Masterbatches

PVC Masterbatches

Black Masterbatches

Colour Masterbatches

That’s why we created a one-stop platform that connects buyers and suppliers in the niche category of Masterbatch worldwide.

Quick Links

Contact Info

Address :

421/C, 4th Floor, Super Mall-1, Gh-0, above SBI Bank, Infocity, Gandhinagar, Gujarat 382007

Phone:

That’s why we created a one-stop platform that connects buyers and suppliers in the niche category of Masterbatch worldwide.

Quick Links

Contact Info

Address

421/C, 4th Floor, Super Mall-1, Gh-0, above SBI Bank, Infocity, Gandhinagar, Gujarat 382007