Transparent Masterbatch

Home » Transparent Masterbatches

Members Arena

Diamond Members

- Black Masterbatch

- White Masterbatch

- Colour Masterbatch

- Rubber Masterbatch

- PVC Masterbatch

- Additive Masterbatch

- Pet Masterbatch

- Mono Concentrated

- Roto Pre Masterbatch

- XLPE Masterbatch

- Universal Masterbatch

- Engineering Masterbatch

- Special Effect Masterbatch

- Bio Degradable

- Masterbatch

Platinum Members

- Black Masterbatch

- White Masterbatch

- Filler Compound

- PP Milky Filler For Non

- Woven Products

- Filler Masterbatch

- Colour Masterbatch

- Additive Masterbatch

- Desiccant Masterbatch

- Optical Brightner

- UV Masterbatch

- PPA Masterbatch

- Anti Slip Masterbatch

- Slip Masterbatch

- Fire Retardant Masterbatch

- Modifier

- Transparent Masterbatch

Silver Members

Riviera Polymers Private Limited was envisaged in 1982. The organization had to become a mark to reckon with in the manufacture of Colour and Additive Concentrates and Special Thermoplastic Compounds. Two decades on, we are living as Brand Riviera and remain the front-runner manufacturer of high-quality Masterbatches and Specialty Thermoplastic Compounds in India.

Share Your Requirements to Get the Best Price

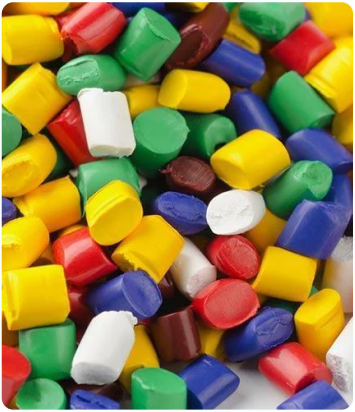

High-Quality Transparent Masterbatch for Superior Clarity

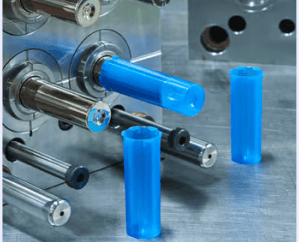

At Masterbatch Manufacturers, we offer the best Transparent Masterbatch designed to improve the clarity, strength, and performance of plastic products. Our formulas are the best option for a range of applications, as they provide exceptional durability, low dust, and good light transmission.

Whether you require exceptional transparency for consumer items, packaging, or industrial applications, our masterbatch produces unmatched results.

How to Choose the Right Transparent Masterbatch?

Choosing the best Transparent Masterbatch depends on several factors, such as:

- Resin Compatibility: Make sure your base polymer (such as PP, PE, PET, PS, or PC) is compatible with the masterbatch.

- Clarity & Haze Level: Select a formulation that satisfies the necessary optical and transparency requirements.

- Thermal Stability: Choose a masterbatch that is resistant to deterioration at processing temperatures.

- UV & Weather Resistance: To increase longevity, use a product with UV stabilisers for outdoor use.

- Regulatory Compliance: Make sure it satisfies industry requirements, particularly for applications involving food and medicine.

Advantages of Using Transparent Masterbatch

There are several advantages to purchasing premium transparent masterbatch from masterbatch manufacturers:

- Exceptional Transparency: Improves the visual appearance of plastic objects while retaining strength.

- Improved Process ability: Guarantees smooth dispersion, which reduces faults and increases manufacturing efficiency.

- Enhanced Durability: Improves resistance to heat, chemicals, and UV exposure.

- Cost-Effective Solution: Eliminates the requirement for expensive clear resins, providing a more affordable option.

- Versatile Applications: It is suitable for extrusion, blow moulding, injection moulding, and thermoforming.

- Colour Customisation: To create unique visual effects, mix with Special Effect Masterbatch.

Applications of Transparent Masterbatch

Transparent Masterbatch is widely utilised in a variety of sectors due to its ability to improve clarity and aesthetics while preserving mechanical qualities. Some important applications include:

- Packaging Industry: Utilised to preserve product visibility in PET bottles, food containers, and transparent films.

- Consumer Goods: Improves the look of plastic products, including storage boxes, cosmetics packages, and household goods.

- Medical Equipment: Guarantees the purity and clarity of pharmaceutical containers, medical tubing, and diagnostic equipment.

- Automotive Parts: Utilised for better visual appeal in translucent interiors, instrument panels, and light covers.

- Industrial Applications: Transparency in injection-molded items, pipes, and sheets for structural and decorative purposes.

How to Source the Best Transparent Masterbatch?

Selecting the best Transparent Masterbatch supplier is essential to getting reliable performance and quality. To make sure you pick the best, follow these steps:

- Partner with a Trusted Manufacturer: Select Masterbatch Manufacturers, an organisation that has a track record of producing masterbatches of superior quality.

- Request Samples & Testing: Assess the compatibility, clarity, and dispersion with your polymer prior to making a large purchase.

- Check Certifications and Standards: Make sure that all legal standards for medical and food-grade applications are met.

- Compare Technical Specifications: Depending on your requirements, consider the haze percentage, light transmission, and melt flow index.

- Explore Customisation Options: Consider using Special Effect Masterbatch to improve the appearance if you require special properties.

Reach Out to Us for Expert Masterbatch Solutions!

We at Masterbatch Manufacturers are proud to provide world-class Transparent Masterbatch that is of the highest quality. Our expert team is committed to offering innovative solutions that improve the clarity, strength, and performance of your plastic products.

Whether you require help in choosing the appropriate masterbatch or need custom-made solutions, we can assist you. Get in touch with us right now to find out how our products can improve yours with better performance and clarity.

Benefits

Improves Product Aesthetics

Maintains Natural Transparency of The Polymer

Provides Excellent Dispersion

Enhances Clarity and Gloss

Compatible with Multiple Polymers

Allows Transparent Color Customization

Safe for Food-Contact Applications

Increases Mechanical Strength

Cost-Effective Solution

Available with UV and Heat Stability Options

Industrial Applications

Transparent Storage Boxes

Flexible Packaging Films

Stationery Items Like Pens and Rulers

Transparent Plastic Toys

LED Light Covers and Electronic Casings

Kitchenware and Household Items

Automotive Indicator Covers and Trims

Blister Packs and Medical Packaging

Transparent Syringes

Cosmetic Caps and Bottles

Clear Bottles and Containers (PET, PP, PE)

Clear Injection-Molded Products

Elevating Plastics with Superior Transparent Masterbatch

Unmatched quality, performance, and customization for every industry.

Frequently Asked Questions

Our FAQ section provides clear answers to common questions about white masterbatches, from product features to application details. We aim to help you understand how our solutions can improve your plastic products. If you have further inquiries, our team is always ready to assist you.

What is a transparent masterbatch used for?

Transparent masterbatch is used to enhance the clarity, gloss, and visual appeal of plastic products without affecting their transparency.

Can transparent masterbatch be used in PET bottles?

Yes, it is widely used in PET bottles for beverages, cosmetics, and personal care due to its high compatibility and clarity.

Does transparent masterbatch affect the clarity of the final product?

No, it is designed to maintain or enhance the natural transparency of the base polymer.

Is transparent masterbatch safe for food-grade applications?

Yes, food-grade transparent masterbatches comply with regulatory standards and are safe for packaging and containers.

What polymers are compatible with transparent masterbatch?

It is compatible with polymers like PP, PE, PET, PS, and ABS, among others.

Can I add color to transparent masterbatch?

Yes, it can be combined with transparent color masterbatches to achieve tinted effects while maintaining clarity.

What is the typical loading percentage of transparent masterbatch?

Loading levels generally range between 1% to 5%, depending on the application and desired transparency.

How does transparent masterbatch differ from natural polymer resin?

Natural resins are unmodified, while transparent masterbatches are additives that enhance clarity, strength, and processability.

Does transparent masterbatch affect the mechanical strength of plastic?

It can improve strength and stiffness without compromising the material’s transparency.

Is UV stability available in transparent masterbatches?

Yes, UV stabilizers can be included to protect the product from sunlight degradation.

What is the shelf life of transparent masterbatch?

Typically, it has a shelf life of up to 12–24 months when stored in a cool, dry place.

Can transparent masterbatch be used in blow molding applications?

Yes, it performs well in blow molding processes used for making bottles, jars, and containers.

Is it suitable for injection molding processes?

Absolutely, it is ideal for injection molding of transparent components and parts.

How does it perform in high-temperature processing?

High-quality transparent masterbatches are thermally stable and perform well in high-temperature processes.

Can it be used in thin film applications without compromising clarity?

Yes, it is suitable for producing ultra-clear thin films for packaging and lamination.

What additives can be combined with transparent masterbatch?

It can be combined with anti-fog, anti-block, UV, and slip agents depending on the application.

How is moisture absorption managed in transparent masterbatch?

Desiccant packaging and proper storage help manage moisture absorption during handling and processing.

Are there any limitations in using transparent masterbatch in outdoor applications?

Without UV stabilizers, long-term outdoor exposure may lead to yellowing or brittleness.

What testing standards does transparent masterbatch comply with?

It typically complies with RoHS, FDA, REACH, and other industry-specific regulations.

Can transparent masterbatch be customized for specific industry needs?

Yes, manufacturers can tailor formulations for industries like automotive, medical, cosmetics, and packaging.

Other Products

Other

Transparent Masterbatches

UV Masterbatch

Special Effect Masterbatches

Engineering Masterbatches

Universal Masterbatches

Biodegradable Masterbatches

Additive Masterbatches

Roto Pre Masterbatch

Mono Concrentrates

XLPE Masterbatches

Rubber Masterbatches

Pet Masterbatches

PVC Masterbatches

Black Masterbatches

Colour Masterbatches