UV Masterbatch Manufacturers

Home » UV Masterbatch

UV Masterbatch Manufacturers - Members Arena

Diamond Members

- Black Masterbatch

- White Masterbatch

- Colour Masterbatch

- Rubber Masterbatch

- PVC Masterbatch

- Additive Masterbatch

- Pet Masterbatch

- Mono Concentrated

- Roto Pre Masterbatch

- XLPE Masterbatch

- Universal Masterbatch

- Engineering Masterbatch

- Special Effect Masterbatch

- Bio Degradable

- Masterbatch

Platinum Members

- Black Masterbatch

- White Masterbatch

- Filler Compound

- PP Milky Filler For Non

- Woven Products

- Filler Masterbatch

- Colour Masterbatch

- Additive Masterbatch

- Desiccant Masterbatch

- Optical Brightner

- UV Masterbatch

- PPA Masterbatch

- Anti Slip Masterbatch

- Slip Masterbatch

- Fire Retardant Masterbatch

- Modifier

- Transparent Masterbatch

Silver Members

Riviera Polymers Private Limited was envisaged in 1982. The organization had to become a mark to reckon with in the manufacture of Colour and Additive Concentrates and Special Thermoplastic Compounds. Two decades on, we are living as Brand Riviera and remain the front-runner manufacturer of high-quality Masterbatches and Specialty Thermoplastic Compounds in India.

Share Your Requirements to Get the Best Price

UV Masterbatch Manufacturers Offering Superior Plastic Protection

Extend the durability and performance of your plastic items with UV Masterbatch from trusted UV Masterbatch Manufacturers. With the intention to safeguard your items from dangerous UV radiation, our high-quality masterbatch delivers high-quality resistance, color maintenance, and longevity.

You can require UV protection for your packaging, car components, agriculture films, or building materials. Whatever you want, our advanced technologies preserve the quality and form of your plastic items for a long time.

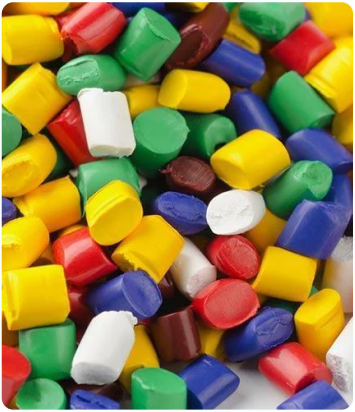

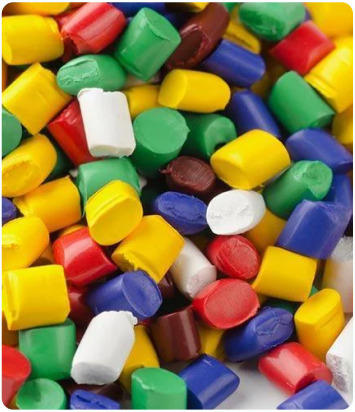

What is UV Masterbatch?

The Filler Masterbatch are vital fillers for minerals, calcium carbonate, powder, and different added substances integrated into plastic products to diminish creation costs without reducing quality. These masterbatches are necessary to improve the handling and selection of plastic products.

The Masterbatches furnish guarantee for the expansion of the plastic’s quality, diminishing creation quality and costs.

Benefits of Using UV Masterbatch

The following are common advantages of adding UV Masterbatch to plastic materials:

- Enhanced UV Protection: It avoids cracking, fading, and brittleness caused by long exposure to sunlight.

- Improved Durability: Ensures the plastic retains its strength and flexibility even under tough applications.

- Warranty & Application Assurance: Useful for several key plastic items, including pipes, films, and automobile components.

- Cost-Effective Solution: Maintains the performance of large-scale agricultural and general-use plastics.

- Enhanced UV Protection: It avoids cracking, fading, and brittleness caused by long exposure to sunlight.

Types of UV Masterbatch

UV Masterbatch is available in a variety of formulations to meet the specific requirements of different sectors.

- Hindered Amine Light Stabilizers (HALS): These compounds are highly UV resistant, thus protecting the plastic’s lifespan.

- Hindered Amine Light Stabilizers (HALS): These compounds are resistant to solar exposure, protecting the breakdown of polymer chains.

- Combination UV Absorber Masterbatch: A combination of HALS and absorbers provides unique UV protection for demanding applications.

- Custom UV Masterbatch: Specially made to fit particular material qualities based on client specifications by leading UV Masterbatch Manufacturers.

Choosing the Right UV Masterbatch

A number of factors determine which UV Masterbatch is best:

- Material Types: Various polymers, including PET, PP, and PE, need particular formulas.

- Application Conditions: Consider exposure intensity, climate, and location for best performance and longevity.

- Regulatory & Environmental Standards: Ensure the Masterbatch fulfills international and local compliance standards.

- Quality Assurance: Always source from reputed suppliers and recognized UV Masterbatch Manufacturers for dependable products.

Why Choose UV Masterbatch Manufacturers?

UV Masterbatch Manufacturers specialize in premium plastic additives that are designed to deliver exceptional performance. Our UV Masterbatch was created in association with reputed UV Masterbatch Manufacturers to prevent, guaranteeing the long-lasting safety of your plastic products. This is what makes our solutions stand out:

- Premium Quality: We make use of advanced formulas and premium smart components.

- Sustainable Production: All UV Masterbatch solutions meet global environmental and industry standards.

- Cost-Effective Additives: A balance of affordability and reliable results.

- Wide Applications: From agriculture to packaging, films, bottles, and automotive, trusted UV Masterbatch Manufacturers provide unmatched reliability.

Explore Our Range of High-Performance Additives

Apart from UV Masterbatch, we provide an array of additives, among which is Engineering Masterbatch, intended for applications with high performance. These additives help industries achieve strength, thermal stability, and improved efficiency.

Our demanding testing facilities and collaboration with major UV Masterbatch Manufacturers bring advanced plastic solutions that ensure maximum durability and efficiency, all set to cater for future formulations and expectations.

Discover more about our products and services by visiting our Masterbatch Manufacturers official website

Benefits

Protects Plastics From UV Degradation

Increases Product Lifespan

Prevents Discoloration and Fading

Maintains Mechanical Strength

Enhances Outdoor Durability

Reduces Surface Cracking and Brittleness

Suitable for Long-Term Sun Exposure

Improves Weather Resistance

Customizable UV Protection Levels

Compatible with Various Polymers

Cost-Effective Additive Solution

Helps Maintain Product Aesthetics

Stabilizes Plastic Properties Over Time

Essential for Outdoor Applications

Reduces Maintenance and Replacement Costs

Industrial Applications

Agricultural Films

Outdoor Furniture and Fixtures

Plastic Roofing Sheets and Panels

Garden Tools and Accessories

Automotive Plastic Parts

Plastic Packaging Exposed to Sunlight

Construction Materials

Geomembranes and Pond Liners

Playground Equipment and Toys

Electrical and Telecom Enclosures

Outdoor Signage and Display Boards

Industrial Containers and Drums

Irrigation Pipes and Components

Marine Plastic Products

Woven Sacks and FIBCs

Elevating Plastics with Superior UV Masterbatches

Unmatched quality, performance, and customization for every industry.

Frequently Asked Questions

Our FAQ section provides clear answers to common questions about white masterbatches, from product features to application details. We aim to help you understand how our solutions can improve your plastic products. If you have further inquiries, our team is always ready to assist you with expert advice and connections to reliable UV Masterbatch Manufacturers.

What is UV Masterbatch?

UV Masterbatch is a concentrated additive used in plastics to protect them from the harmful effects of ultraviolet (UV) radiation.

How does UV Masterbatch work?

It contains UV stabilizers or absorbers that either absorb harmful UV rays or neutralize their effects, preventing polymer degradation.

Why is UV protection important in plastics?

Without UV protection, plastics can become brittle, discolored, and lose strength when exposed to sunlight over time.

What types of plastics can UV Masterbatch be used with?

It is compatible with polymers like PE, PP, PVC, PET, ABS, and others.

In which industries is UV Masterbatch commonly used?

It is widely used in agriculture, packaging, automotive, construction, and consumer goods industries.

Is UV Masterbatch suitable for outdoor applications?

Yes, it is specifically designed for products exposed to sunlight or harsh weather conditions.

Does UV Masterbatch affect the transparency of plastic?

Some UV stabilizers may slightly reduce clarity, but specialized grades are available for transparent applications.

What is the typical dosage of UV Masterbatch?

It usually ranges from 1% to 5% depending on polymer type, application, and required UV resistance.

Can UV Masterbatch be combined with color Masterbatch?

Yes, it can be blended with color or other additive masterbatches during processing.

What is the shelf life of UV Masterbatch?

Generally, it has a shelf life of 12 to 24 months if stored properly in cool, dry conditions.

Is UV Masterbatch safe for food-contact applications?

Yes, food-grade UV Masterbatches are available and comply with FDA or EU regulations.

Does it protect against both UVA and UVB rays?

Yes, advanced UV Masterbatches offer broad-spectrum protection covering both UVA and UVB.

Can it be used in films and injection-molded items?

Absolutely, UV Masterbatch is suitable for various plastic processing methods including film blowing, extrusion, and injection molding.

Does it change the color of the final product?

Generally no, but certain UV stabilizers may slightly influence the shade in light-colored or transparent products.

Can UV Masterbatch improve product lifespan?

Yes, it significantly extends the life of plastic products used outdoors by reducing degradation.

Is UV Masterbatch required for indoor applications?

Not usually, unless the plastic is exposed to strong artificial lighting or occasional sunlight.

How is UV resistance measured in plastics?

UV resistance is often tested using accelerated weathering tests like QUV, with results measured in hours of exposure.

Does it prevent yellowing of plastic?

Yes, UV Masterbatch helps reduce yellowing and maintains the visual appeal of plastics.

Can it be used in colored plastic products?

Yes, and it is often used in combination with color masterbatches to maintain shade stability.

What is the difference between UV Absorbers and UV Stabilizers?

UV absorbers block and absorb UV rays, while stabilizers neutralize free radicals created by UV exposure, offering complementary protection.

Other Products

Other

Transparent Masterbatches

UV Masterbatch

Special Effect Masterbatches

Engineering Masterbatches

Universal Masterbatches

Biodegradable Masterbatches

Additive Masterbatches

Roto Pre Masterbatch

Mono Concrentrates

XLPE Masterbatches

Rubber Masterbatches

Pet Masterbatches

PVC Masterbatches

Black Masterbatches

Colour Masterbatches